Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

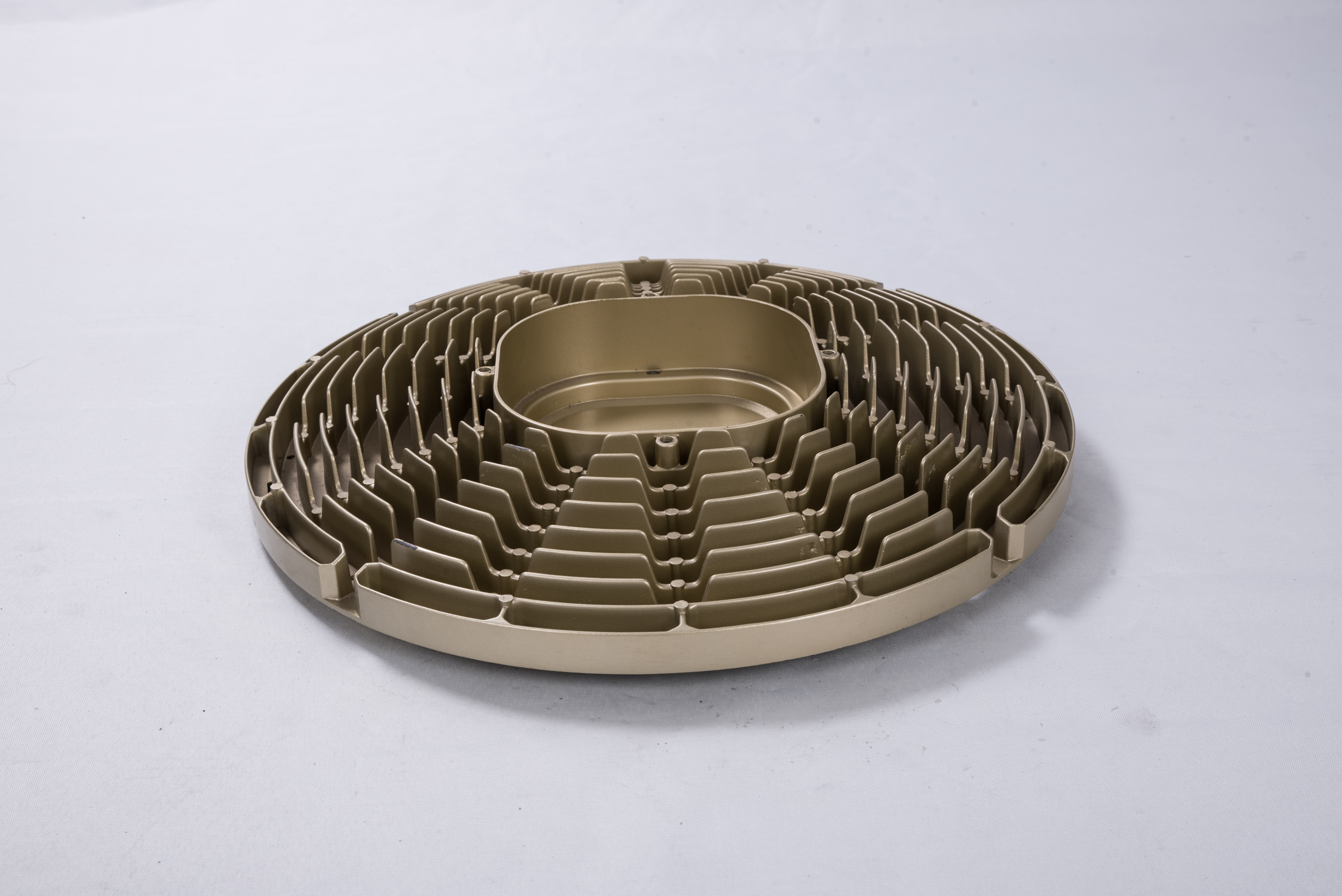

OEM Aluminum Alloy Die Casting For LED Bay Light Radiator Parts

OEM Aluminum Alloy Die Casting For LED Bay Light Radiator Parts

-

USD 1.00 ~ USD 5.00/piece

500/ piece (Min. Order)

Contact us

Inquiry Basket

OEM:

Available

Sample:

Refuse

Port:

Ningbo

Payment:

L/C,T/T,D/P,D/A

Place of Origin:

China

Supply Ability:

200000 piece per Month

1. One-stop solution from mold design and development, die-casting manufacturing, fine machining, surface treatment, assembling.

2. Own factory production, in-house mold workshop, reasonable prices

3. More than 20 years of experience in quality die casting manufacturing

4. IATF16949:2016 Certificated

5. With the European market since 2010

Technics & process Aluminum alloy die casting: 44300,44300/46000/ADC12/A360/A380/Alsi9cu3,etc.

Aluminum alloy profile extrusion: 6061 6063

CNC machining and Turning: 6061 6063

Part Weight: From 10g to 15000g

Mould manufacture: Part design drawing (prt/fem/igs/stp/dxf/model/x-t/x-b forms)-mould making-sample supplied

Equipment Cold chamber dies casting machine:200T/280T/400T/500T/800T/1250T.CNC centers, CNC turning, CNC lathes, electrical pulse, line cutting, milling, drilling, grinding

Surface Treatment Trimming, Deburring, Polishing, Shot blasting, Sand blasting, Tumbling, Powder coating, Anodizing, Chrome, Zinc, Electrophoresis, Passivation, Chemical coating.

Software Assistance Pro-e/Solid work/UG/Auto CAD/CATIA

Products Application Automotive industry

Bicycle and motorcycle

Door and windows and furniture

Household appliance

Gas meter

Power tool

LED lighting

Medical instrument parts

Manufacture Process:

1.Review the part design, drawings, and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Mass production

5.Surface treatment: Trimming, Deburring, polishing, cleaning, passivation & powder coating and other requirements from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding, etc

7. Full Inspection

8. Packing

9. Delivery

Service:

1. OEM and ODM.

2. Quotation within 24 hours.

3. Inspection service by SGS or any other inspection assigned by the Customer.

4. Shipping service.

5. After service

Why choose us:

1.Our technical know-how and experience team ensure us being able to offer the service with International standards towards our customers.

2.Rely on International tooling designing concept and manufacturing, we could build a tailor-made tool to satisfy your product quality requirement.

3.Equipped unique with top performance die casting machines and CNC machines to produce high precision products.

4.The strong application technical support towards the customer in the project development phase which different from the other suppliers. Our mission is building long term co-operation with our customers

Contact us